- Home /

- DOOR HARDWARE /

- DOOR HARDWARE ACCESSORIES /

- LOCKWOOD /

- LOCKWOOD VIVID EDGE PULL SATIN BRASS TP SATIN BRASS PVD

Shop Now

- ACCESS CONTROL

- ALARM SYSTEMS

- AUTOMOTIVE SECURITY

- CCTV

- DOOR HARDWARE

- ELECTRONIC LOCKING

- EMERGENCY SERVICES LOCKS

- INTERCOM SYSTEMS

- KEY BLANKS

- KEYS & ACCESSORIES

- LOCK CYLINDERS

-

LOCKS

- AUTOMOTIVE LOCKS

- BOLTS

- CAM LOCKS & ACCESSORIES

- CUPBOARD LOCKS & ACCESSORIES

- DEADLOCKS

- DEADLOCKS ACCESSORIES

- DOMESTIC

- ENTRANCE LOCKS

- GARAGE LOCKS & ACCESSORIES

- KEY IN KNOB

- KEY IN LEVER

- LOCKS SPARE PARTS

- MECHANICAL DIGITAL LOCKS

- MORTICE LOCKS

- POOL AND GATE LOCKS

- SCREEN DOOR LOCKS

- SLIDING DOOR LOCKS AND ACCESSO

- WINDOW LOCKS AND ACCESSORIES

- LOCKSMITH TOOLS

- MECHANICAL

- NETWORKING TOOLS

-

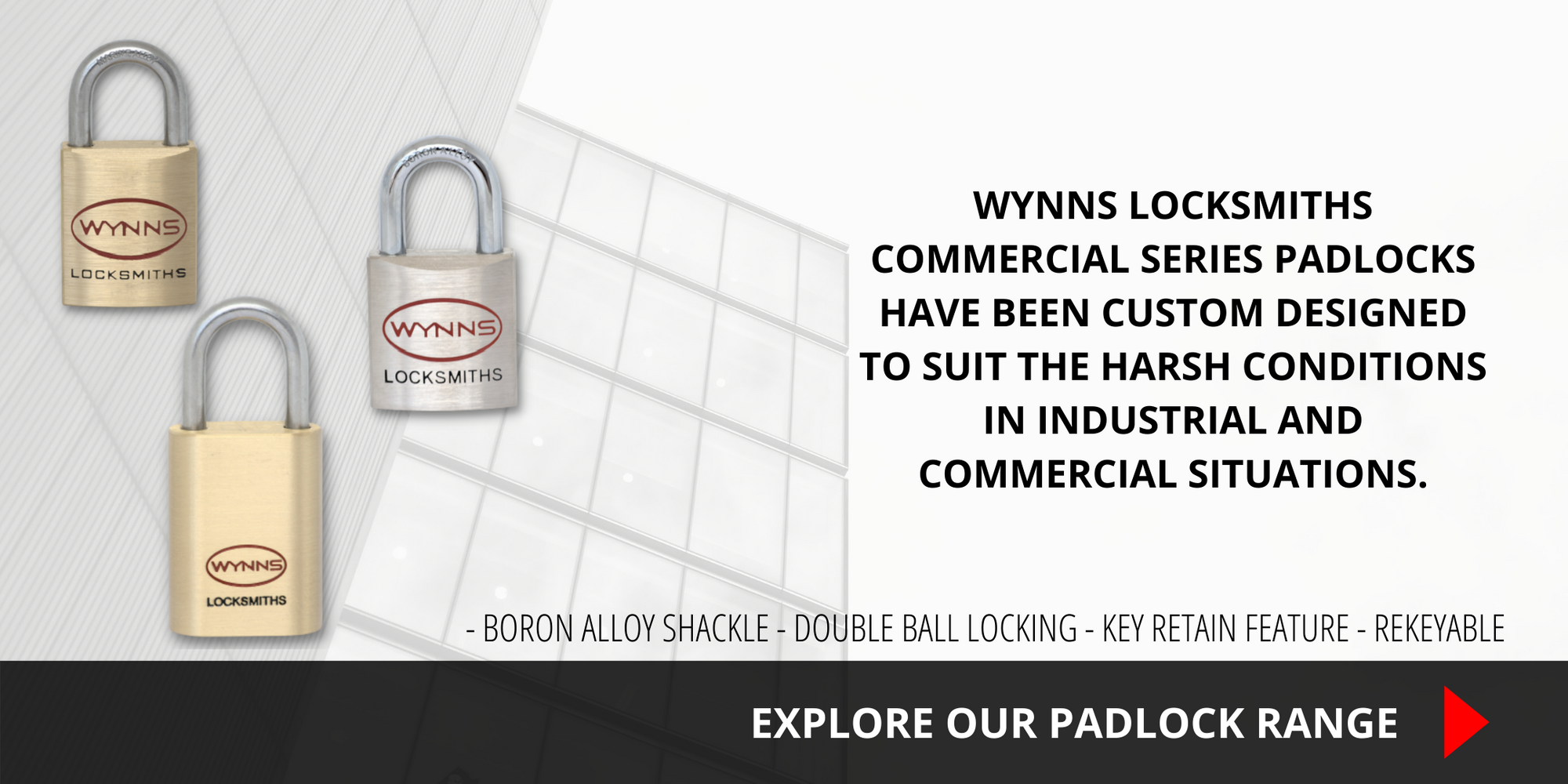

PADLOCKS & ACCESSORIES

- ABUS PADLOCKS

- CABLES & CABLE LOCKS

- CHAIN

- HASP & STAPLES/PADBOLTS

- LUGGAGE LOCKS

- PADLOCK ACCESSORIES

- PADLOCKS

- WYNNS 30MM PADLOCK

- WYNNS 40MM PADLOCK

- WYNNS 50MM PADLOCK

- WYNNS 6 PIN 40MM PADLOCK

- WYNNS 6 PIN 45MM PADLOCK

- WYNNS 6 PIN 50MM PADLOCK

- WYNNS 6 PIN 55MM PADLOCK

- WYNNS COMBINATION PADLOCK

- WYNNS PADLOCKS

- SAFES

- SECURITY EDGE

- SECURITY EDGE 5 PIN EURO CYLIN

- SECURITY EDGE BARRELS

- SECURITY EDGE L SERIES CYLINDE

- SECURITY EDGE L SERIES PADLOCK

- SECURITY EDGE PRODUCTS

-

SECURITY EDGE S SERIES CYLINDE

- 001 S SERIES INNER CYLINDERS

- 201 S SERIES ROUND CYLINDERS

- 355 S SERIES INNER CYLINDERS

- 530 S SERIES KNK CYLINDERS

- 570 S SERIES OVAL CYLINDERS

- 670 S SERIES CAM LOCKS

- 8090 S SERIES TRILOCK CYLINDER

- 8217/5 S SERIES ASTRA OVAL CYL

- 8221 S SERIES PD CYLINDERS

- 8466 S SERIES KAWNEER CYLINDER

- EURO S SERIES FIXED CAM CYLIND

- EURO S SERIES FIXED CAM MODULA

- EURO S SERIES LAZY CAM CYLINDE

- SECURITY EDGE S SERIES PADLOCK

LOCKWOOD VIVID EDGE PULL SATIN BRASS TP SATIN BRASS PVD

Description

The Lockwood Vivid® Collection Cavity Sliding Door Edge Pull is used as a pull handle on the edge of the sliding or pocket doors. It is designed to be flush mounted to your door and comes in three coloured PVD finishes to match the rest of the products in the Vivid® Collection.

Application

Suited to numerous applications which require the door furniture to be flush with the edge of the door. It also can be used in combination with a flush pull to create a passage solution for any internal room where the door is fully pocketed into the wall cavity.

PVD coating

The Vivid® Collection’s three finishes are derived from a physical vapor deposition (PVD) surface treatment which offers a range of benefits, including sustainability and durability. PVD coatings exhibit unparalleled hardness, with four times the robustness of chrome, along with superior scratch and wear resistance, and reduced susceptibility to corrosion. In addition, PVD coatings do not emit toxic liquids or gases during manufacturing, making them a cleaner and safer method of production.